Since 2013, Gaogong lithium battery Golden Globe Award has been successfully held for three times, which has received high attention from the whole lithium battery industry and the active participation of enterprises in industry segments. It has become the most authoritative selection activity in the industry and is known as the "Oscar in lithium battery industry". In order to encourage technological innovation and brand innovation, record and look back on the growth process of China's lithium battery enterprises and major reform forces in the industry over the past year, high tech lithium battery once again launched the 2016 high tech Golden Globe Award.

With the theme of "looking for new power in the industry", this Golden Globe Award will be registered from June 1. Enterprises can introduce themselves and register through Gaogong lithium power grid or pay attention to Gaogong lithium's official wechat platform. At present, the Golden Globe Award application has been closed, and Shenzhen Sunka Lead Electromechanical Equipment Co., Ltd. (hereinafter referred to as "Sunka lead") has applied for the Golden Globe Award "annual excellent automation production line" award.

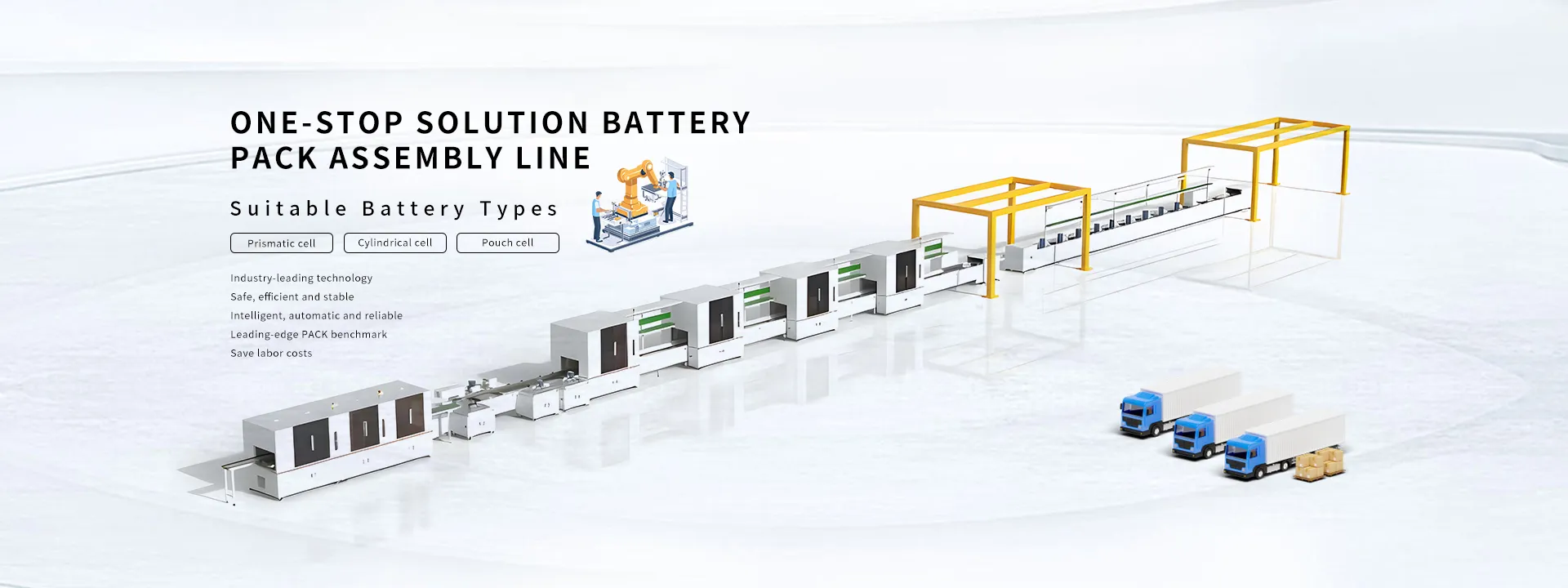

Sunka lead is a high-tech enterprise mainly engaged in the research, development and manufacturing of automatic assembly, automatic testing, high-precision non-standard intelligent equipment and other automation in the lithium battery industry. The company has domestic leading technology, a number of invention patents, utility model patents, and independent intellectual property rights. With a high-quality talent team with many years of working experience in the fields of lithium batteries, packs and non-standard automation, we can customize various automation solutions for customers, so as to greatly improve the production efficiency and product quality of the enterprise.

In the mass production mode, in order to ensure the safety and consistency of power batteries, it has become the consensus of battery enterprises to adopt excellent automatic production lines to replace the traditional production mode, and it also puts forward higher requirements for equipment manufacturers.

Tan Jun, the leading deputy general manager of sunka, told Gaogong lithium power grid that the power 18650 automated pack production line developed by the company has the characteristics of automation, intelligence, flexibility and digitalization. Targeted for small and medium-sized power battery enterprises to provide power, energy storage, electric tools 18650 battery pack pack production line, to meet different customers' different product and process needs. The flexible production line, MES and machine vision are combined to create a closed-loop production of power battery packs, which is especially suitable for new enterprises in the field of power batteries.