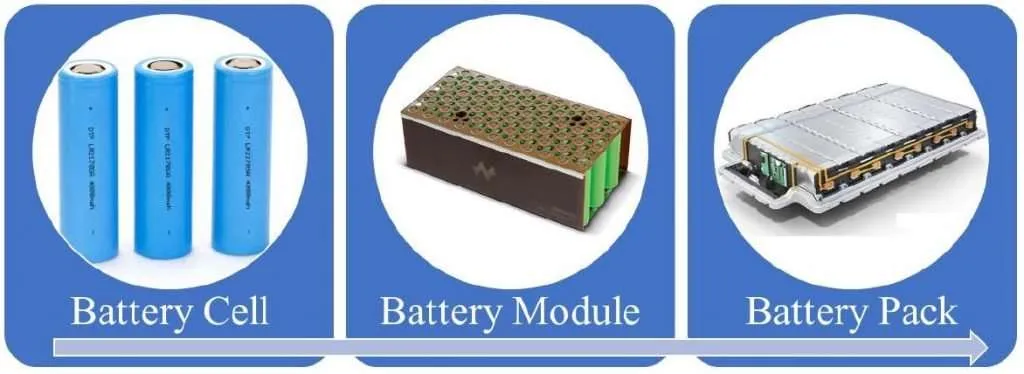

In the world of battery technology, terms like battery module and battery pack are often used interchangeably, but they refer to different components of a battery system. Understanding the difference between a battery module and a battery pack is crucial for anyone working with energy storage, whether for electric vehicles (EVs), renewable energy systems, or portable electronics. This article will break down the definitions and differences between a battery module and a battery pack.

What is a Battery Module?

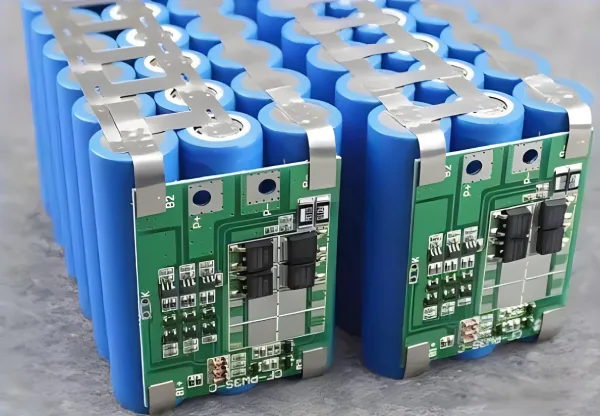

A battery module is a collection of individual battery cells connected together in a specific arrangement. These cells are typically wired in series or parallel, depending on the voltage and capacity requirements. A battery module contains not only the cells but also the essential electronics for managing cell performance, such as Battery Management Systems (BMS), protection circuits, and temperature sensors.

Key Features of a Battery Module:

Cell Arrangement: Battery modules usually consist of several battery cells (Li-ion or LiFePO4) arranged in series or parallel to achieve the desired voltage and capacity.

Battery Management System (BMS): The BMS ensures proper monitoring of cell voltage, temperature, and charging/discharging cycles to maintain safe and efficient operation.

Thermal Management: Modules may include cooling mechanisms to regulate temperature, preventing overheating or thermal runaway.

Battery modules are typically used as subcomponents in larger energy storage systems. They offer more flexibility in the design and expansion of battery systems.

What is a Battery Pack?

A battery pack is a fully assembled unit that consists of multiple battery modules connected together to form a complete energy storage system. A battery pack typically includes the modules, a Battery Management System (BMS), cooling systems, safety features, and external connections to integrate the pack with the end-use application, such as an electric vehicle or a stationary energy storage system.

Key Features of a Battery Pack:

Multiple Modules: A battery pack is made up of several battery modules connected in series and parallel to meet the required voltage and capacity.

Complete Energy Storage Solution: In addition to the modules, a battery pack includes integrated components for safety, management, and cooling.

Application Integration: Battery packs are designed for specific applications, including EVs, consumer electronics, or large-scale energy storage systems. They are designed to be plug-and-play, ready for installation.

Battery packs are typically the final product delivered to customers, providing a complete solution for energy storage needs.

Key Differences Between a Battery Module and a Battery Pack

Size and Scale:

A battery module is a smaller unit, usually containing several cells. It serves as a building block in larger systems.

A battery pack is a larger, fully integrated system that includes multiple modules and additional components like a BMS and cooling system.

Functionality:

A battery module focuses on storing energy and providing the appropriate voltage and capacity for the application.

A battery pack is designed to provide a complete energy storage solution, integrating modules into a system that is ready to be installed and used in real-world applications.

Application:

Battery modules are often used in situations where the user needs to customize the battery system's size, voltage, or capacity, such as in stationary energy storage systems.

Battery packs are typically used in devices where a pre-assembled, complete energy solution is needed, such as electric vehicles, consumer electronics, or grid-scale energy storage.

Why Understanding the Difference is Important

For manufacturers, engineers, and consumers, understanding the difference between a battery module and a battery pack is essential when designing or selecting energy storage systems. This knowledge helps in:

Customization: Choosing between modules or packs allows for better optimization based on specific voltage, capacity, and performance requirements.

Efficiency: Using battery modules can offer more flexibility and efficiency in scaling the energy system to meet varying application needs.

Safety and Reliability: Knowing the components of a battery system allows better management of safety features, such as thermal management, BMS, and cell balancing.

How SUNKA LEAD Can Help You with Battery Pack and Module Solutions

At SUNKA LEAD, we specialize in providing cutting-edge solutions for battery pack assembly and testing machines. Whether you’re designing a battery module for a large-scale energy storage project or assembling a battery pack for electric vehicles, our advanced machinery ensures that your battery system is safe, efficient, and high-performance.

Our battery module testers and battery pack assembly machines help you test, assemble, and optimize your battery systems with precision. We ensure that each component meets the highest standards, helping you deliver reliable energy storage solutions to your customers.

Contact SUNKA LEAD today to learn more about how our equipment can improve your battery production process.