Lithium batteries are vital for powering electric vehicles, energy storage systems, and consumer electronics. A critical aspect of battery pack production is ensuring reliable connections within the pack. While direct welding may seem feasible, industry experts overwhelmingly favor spot welding for its safety, efficiency, and reliability. Here's why:

1. Challenges of Direct Welding Lithium Battery Cells

Heat Sensitivity

Lithium-ion cells, especially cylindrical ones, are highly sensitive to temperature. Direct welding, which involves high temperatures often exceeding 300°C, risks causing:

Electrolyte evaporation

Separator damage

Cell swelling or leakage

Thermal runaway, a severe safety hazard.

Weak Connection Durability

Lithium battery cells experience expansion and contraction during charge and discharge cycles, coupled with exposure to vibrations and temperature fluctuations. Welded joints often lack the robustness to withstand these stresses, leading to poor contact and reduced battery life.

2. Spot Welding: A Superior Alternative

Spot welding addresses the shortcomings of traditional welding by using a controlled application of heat over a short duration, creating stronger and safer connections. Its key benefits include:

Precise Heat Control

Spot welding generates localized heat in milliseconds, safeguarding the cell's internal structure from thermal damage.

Stronger Mechanical Bonds

The mechanical connections formed during spot welding are highly durable, capable of withstanding the rigors of battery pack operation.

High-Volume Production Efficiency

Spot welding supports automation, enabling consistent, high-speed production for large-scale operations without compromising quality.

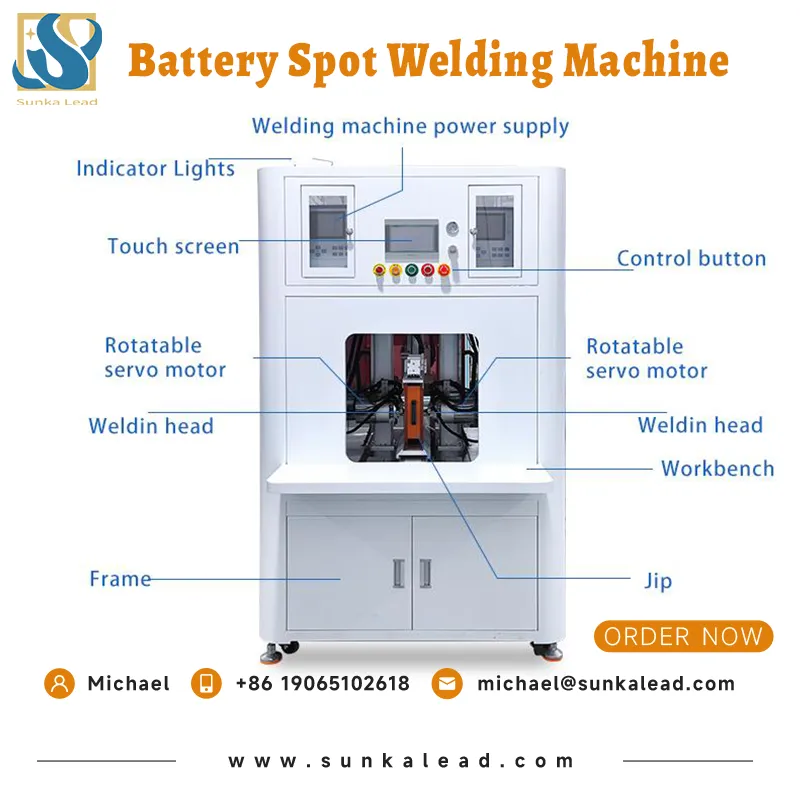

3. SUNKA LEAD: Advanced Spot Welding Solutions

SUNKA LEAD specializes in cutting-edge spot welding equipment tailored for lithium battery production. Key features of our spot welders include:

Advanced Heat Management

Our spot welders prevent overheating with precise temperature controls, ensuring cell integrity.

Compatibility with Multiple Cell Types

Designed to handle 18650, 21700, and other lithium-ion cells, our welders offer versatility for diverse production needs.

High-Speed Automation

Automated systems deliver rapid, consistent welding for enhanced productivity.

Reliable, Long-Lasting Connections

Strong welds ensure the safety and longevity of lithium battery packs, minimizing operational risks.

Elevate Your Battery Pack Production with SUNKA LEAD

SUNKA LEAD’s spot welding solutions are designed to enhance the safety, efficiency, and reliability of your lithium battery packs. Whether you're scaling production or ensuring consistent quality, our advanced technology supports your goals with precision and dependability.

For more information, contact SUNKA LEAD today and transform your battery production processes.