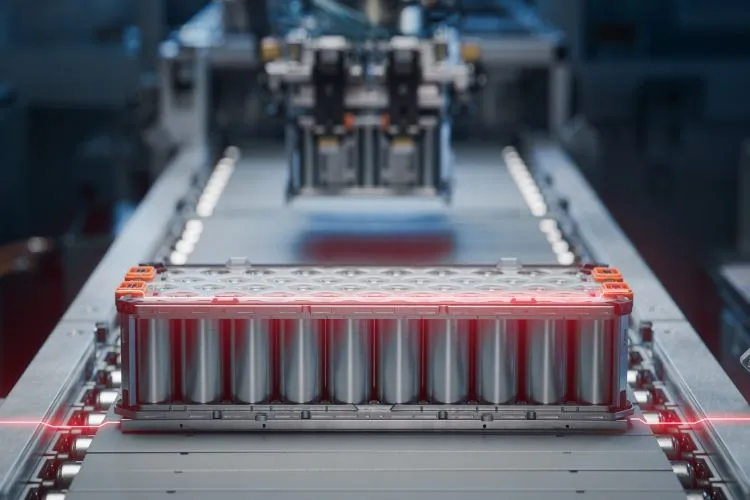

With the rapid development of electric vehicles and renewable energy storage, the quality and safety of batteries have become crucial. Among various types of batteries, cylindrical batteries are widely used in various devices and electric vehicles due to their high energy density and good heat dissipation performance. To ensure battery consistency and reliability, using CCD (Charge-Coupled Device) inspection equipment to inspect cylindrical batteries has become an important method.

I. Principles of Cylindrical Battery CCD Inspection Equipment

CCD inspection equipment mainly uses CCD cameras to capture the appearance of the battery and analyzes the surface quality and dimensional accuracy of the battery through image processing technology. This equipment can automatically detect defects on the battery surface, such as scratches, dents, stains, and other anomalies. Its working principles are as follows:

1. Image Acquisition: The CCD camera takes comprehensive images of the battery to obtain high-definition pictures.

2. Image Processing: Computer vision technology processes the images and extracts feature information of the battery.

3. Defect Detection: Image algorithms analyze the battery surface quality and identify potential defects.

4. Data Analysis: The inspection results are statistically analyzed to determine the overall quality level of the batteries.

II. Advantages of CCD Inspection Equipment

1. High Precision: CCD cameras can capture minute defects, ensuring high accuracy and reliability of the inspection.

2. High Efficiency: Automated inspection equipment significantly improves inspection efficiency, suitable for large-scale production lines.

3. Non-Contact Inspection: It avoids potential damage to the battery surface caused by traditional contact inspection methods.

4. Data Recording: All inspection data can be stored and analyzed, facilitating quality tracking and improvement.

III. Challenges of CCD Inspection Equipment in Practical Application

Despite the many advantages of CCD inspection equipment, there are still some challenges in practical applications:

1. Complexity of Image Processing Algorithms: Different defects have different characteristics, requiring image processing algorithms to be highly complex and adaptable.

2. High Equipment Cost: High-precision CCD cameras and complex image processing systems result in high equipment costs.

3. Strict Environmental Requirements: CCD inspection requires high standards of light and environmental cleanliness, necessitating a clean environment for the inspection process.

In the battery manufacturing process, ensuring the quality and safety of every battery is crucial. As an advanced inspection method, CCD inspection equipment can significantly improve inspection accuracy and efficiency, reducing human error and enhancing the overall quality of the products. However, with the development of technology and the expansion of application scales, how to reduce equipment costs, optimize inspection algorithms, and adapt to a broader production environment will become important issues to address in the future.

I believe that with continuous technological advancements, CCD inspection equipment will play an increasingly important role in the battery manufacturing field, providing strong support for the popularization of electric vehicles and renewable energy.

In summary, cylindrical battery CCD inspection equipment plays a significant role in improving battery quality and safety. Through continuous technological innovation and optimization, we have reasons to believe that CCD inspection equipment will play a greater role in the future, promoting the development of the electric vehicle and renewable energy industries.