In battery manufacturing, product quality and consistency are paramount to ensure the safety, performance, and reliability of the final product. A single defect in the production process can lead to significant issues, including compromised battery life, reduced efficiency, and potential safety hazards. This is where a CCD (Charge-Coupled Device) inspection system comes into play. By incorporating advanced visual inspection technology, a CCD system significantly improves quality control and helps reduce defects in battery production.

The Role of a CCD Inspection System in Battery Production

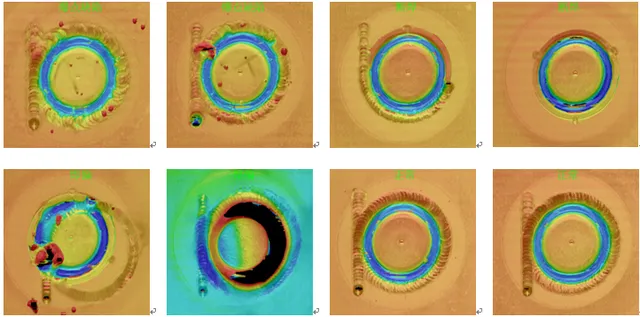

A CCD inspection system uses high-resolution cameras and sophisticated image processing software to detect defects, measure dimensions, and ensure the precise alignment of components during the manufacturing process. Here's how it helps:

Precise Visual Inspection: CCD cameras capture high-quality images of battery components, allowing the system to detect minute defects, such as misalignment, scratches, or contaminants that may be invisible to the human eye. This ensures that only high-quality components proceed to the next stage of production.

Enhanced Quality Control: By integrating a CCD inspection system, manufacturers can implement continuous quality monitoring throughout the production line. This not only reduces the occurrence of defects but also allows for real-time adjustments to improve the process, ensuring consistent product quality.

Automated Detection of Common Defects: Common issues such as incorrect assembly, poor welds, or defective insulation can be detected early through CCD inspection, preventing costly mistakes and minimizing waste. This automation speeds up the production process while maintaining a high standard of quality.

Increased Production Efficiency: A CCD inspection system operates at high speeds, allowing for quick detection and sorting of defective parts without slowing down production. This helps manufacturers maintain high throughput while minimizing the chances of defects slipping through the cracks.

Data-Driven Insights: With its advanced imaging technology, the CCD system provides valuable data and analytics on the production process. This data can be used to track performance, identify trends, and make data-driven decisions to further improve production quality.

SUNKA LEAD's CCD Inspection System: Precision and Reliability

At SUNKA LEAD, we understand that quality is critical in battery manufacturing. Our CCD inspection system is designed to streamline your quality control process by providing:

High Accuracy: Our CCD system delivers precise measurements and defect detection with exceptional accuracy, ensuring that all components meet the highest standards.

Faster Production Cycles: The automated system speeds up the inspection process, enabling your production line to maintain high efficiency without compromising on quality.

Versatile Application: Our CCD inspection system can be customized to inspect a wide range of battery components, including cells, electrodes, and assemblies, making it a versatile tool for various battery types.

Real-Time Feedback: With real-time feedback and analytics, you can identify and address issues instantly, minimizing downtime and optimizing your production process.

Conclusion

The integration of a CCD inspection system into battery production lines is a game-changer for manufacturers looking to reduce defects, enhance quality control, and improve efficiency. With its ability to detect even the smallest defects, provide data-driven insights, and automate the inspection process, it ensures that only the best-quality batteries reach the market.

At SUNKA LEAD, our CCD inspection system is engineered to help you maintain the highest standards of battery production while optimizing your manufacturing processes. Reach out to us today to learn more about how our advanced inspection technology can elevate your production line.