When selecting a laser welding machine for battery assembly, several factors must be considered to ensure high efficiency, precision, and long-term reliability. Laser welding technology is essential in the production of battery packs, offering superior welding quality, speed, and flexibility. Here's a guide to help you choose the right laser welding machine for your battery manufacturing process.

1. Precision and Quality of WeldsThe most critical factor when choosing a laser welding machine is the precision and quality of the welds it can produce. For battery assembly, ensuring a clean, strong, and consistent weld is vital for safety and durability. Look for machines with advanced laser control and automatic monitoring features to guarantee top-notch welds with minimal heat impact on the battery components.

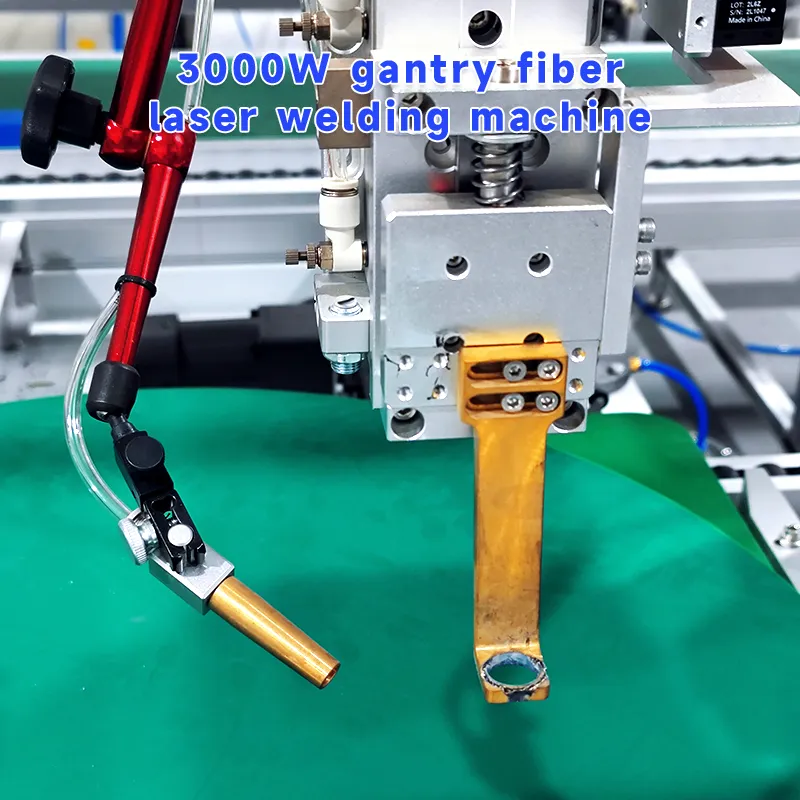

2. Power and Energy EfficiencyLaser welding machines vary in power capacity, which affects welding speed and material compatibility. For battery applications, particularly in lithium-ion battery production, it’s essential to choose a machine that offers the right balance between power and energy efficiency. Machines that are energy-efficient, such as our SUNKA LEAD laser welding machine, not only reduce operating costs but also contribute to eco-friendly production processes.

3. Speed and FlexibilityA fast and flexible welding machine is crucial in high-volume battery production environments. Laser welding machines with adjustable settings allow manufacturers to tailor the machine's parameters based on specific battery designs and materials. SUNKA LEAD’s laser welding machines are designed to provide high-speed operation while maintaining flexibility, making them ideal for varying battery sizes and configurations.

4. Durability and MaintenanceChoosing a durable and low-maintenance laser welding machine is essential to minimize downtime and reduce long-term operating costs. Opt for machines made with high-quality materials and components that are built to withstand continuous use in industrial settings. SUNKA LEAD’s laser welding machines are engineered for long-lasting performance and require minimal maintenance, ensuring smooth operations in your battery assembly line.

5. Safety FeaturesSafety should always be a top priority when selecting welding equipment. Look for laser welding machines that come with comprehensive safety features such as automatic shutdown, protective enclosures, and integrated cooling systems. Our laser welding machines are equipped with advanced safety mechanisms to ensure a secure working environment for operators.

6. Cost-effectivenessWhile laser welding machines may have a higher upfront cost, their efficiency, precision, and reduced material waste can significantly lower production costs in the long term. By investing in high-quality machines like the SUNKA LEAD battery laser welding machine, manufacturers can benefit from long-term cost savings through increased production speed and fewer rework requirements.

Conclusion: Why Choose SUNKA LEAD Laser Welding Machines?

When it comes to battery assembly, choosing the right laser welding machine can drastically improve production efficiency and product quality. SUNKA LEAD’s laser welding machines are specifically designed to meet the high standards required for battery assembly, offering precision, energy efficiency, and durability. Whether you’re assembling lithium-ion battery packs or other battery types, SUNKA LEAD provides the advanced technology you need for optimized manufacturing processes.

Contact us today to learn more about our laser welding machines and how they can enhance your battery production lines.