As the new energy vehicle industry grows, so does the need to recycle and reuse its key components—especially power batteries. Battery recycling presents a unique opportunity to "mine gold" from used batteries by recovering valuable metals like lithium, cobalt, and nickel. With a market potential exceeding one trillion yuan, this sector is poised for substantial growth, driven by the increasing volume of retired batteries and advancements in recycling technologies.

The Emerging Opportunity

The typical lifespan of power batteries is around 6-8 years, meaning the battery recycling industry often lags behind the new energy vehicle market. However, this dynamic is shifting. A significant wave of battery retirements is expected between 2024 and 2025, with potentially one million vehicles retiring their batteries. By 2030, the volume of retired batteries could reach 831 GWh globally, translating to a recycling market valued at about 189.5 billion yuan.

Two Main Methods: Dismantling and Recycling

When it comes to extracting value from used batteries, there are two primary methods: dismantling and recycling.

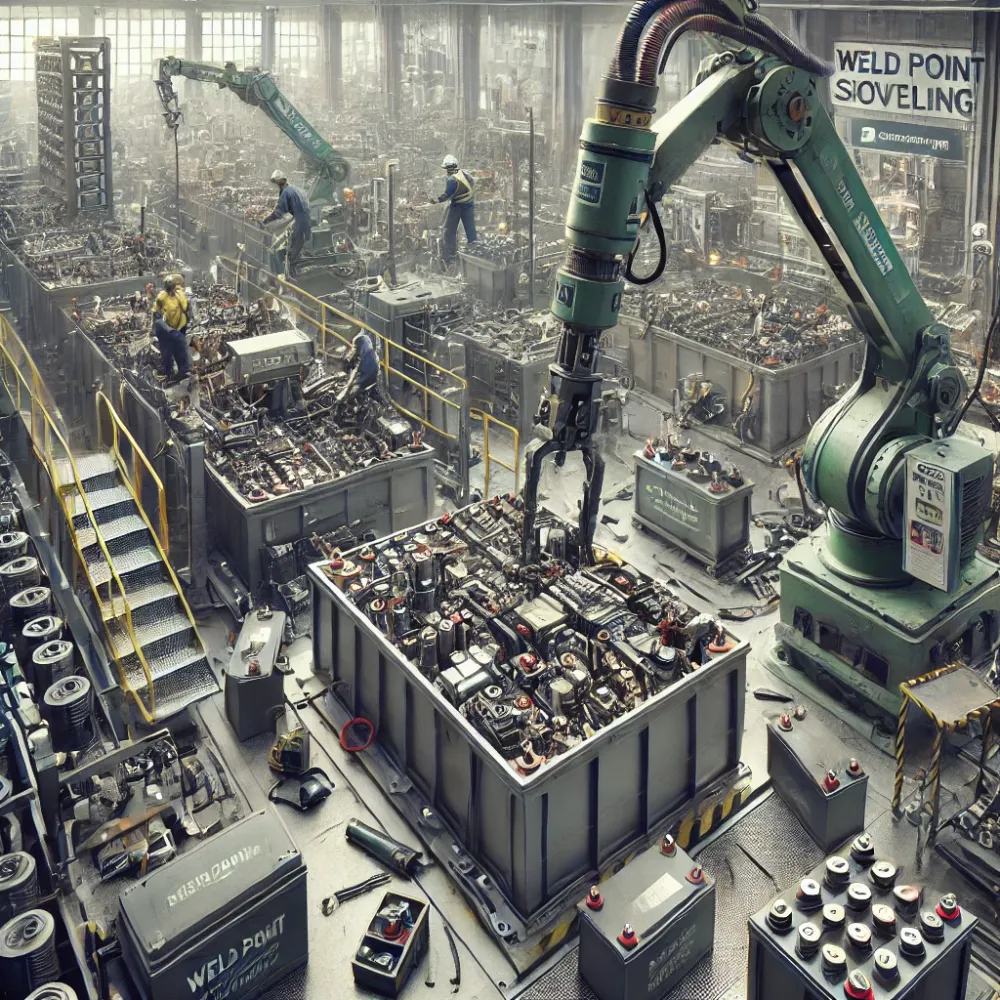

1. Dismantling: This involves disassembling the battery into individual cells and components, followed by the removal of weld points using specialized equipment like a weld point shoveling machine. This method allows for the selective reuse of certain parts and materials. While it can be complex and labor-intensive, dismantling is effective for preparing batteries for further recycling processes and for extracting certain reusable components.

2. Recycling: In this process, various elements such as lithium, nickel, and cobalt are extracted from the dismantled batteries. Advanced chemical and physical processes are used to separate and recover these valuable metals, which can then be reused in the production of new batteries or other products. This method focuses on maximizing the recovery rate of valuable elements, directly influencing profitability.

Strategies for Extracting Value

To capitalize on the growing battery recycling market, companies need to focus on these strategies:

1. Advanced Technology for Higher Recovery Rates: Companies that leverage cutting-edge technologies to increase the recovery rates of valuable metals, such as lithium, stand to gain the most. For instance, increasing the lithium recovery rate from 90% to 95% can boost the unit recycling gross profit significantly—from 700 yuan per ton to 2,300 yuan per ton. Each percentage point improvement in recovery rate leads to an average gross profit increase of 322 yuan.

2. Efficient Channel Development: Establishing a reliable network for sourcing waste batteries is crucial. A strong supply chain allows companies to obtain raw materials consistently and at lower costs, ensuring profitability despite fluctuations in metal prices.

3. Scaling Up Operations for Cost Efficiency: Companies that scale up their operations can benefit from reduced manufacturing costs per unit, maximizing profitability. Combining efficient processes with large-scale operations enables recycling companies to optimize their economic outcomes.

Overcoming Challenges in the Industry

Historically, the battery recycling industry has faced challenges such as unstable pricing and the dominance of small, unregulated workshops. However, recent changes in policy and market conditions have created a more favorable environment:

· Regulatory Support: The Ministry of Industry and Information Technology (MIIT) has tightened regulations by revoking the "white list" status of non-compliant battery recycling companies. This move is expected to clear out smaller players and consolidate the industry, enabling more organized companies to thrive.

· Stabilizing Lithium Prices: With lithium carbonate prices stabilizing and the gap between futures and spot prices narrowing, the pricing environment for battery recycling is becoming more predictable. This stability is crucial for companies aiming to hedge against metal price fluctuations and maintain steady processing profits.

Conclusion: Now is the Time to Mine

With regulatory support, stabilizing prices, and advancements in recovery technology, the battery recycling industry is on the brink of a breakthrough. Companies that strategically invest in technology, develop strong supply channels, and scale their operations can "mine gold" from used batteries, turning waste into wealth.