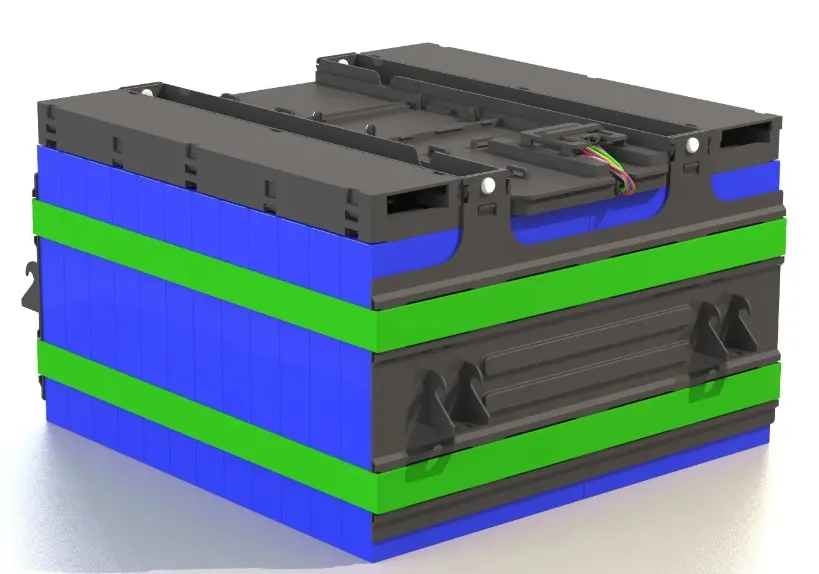

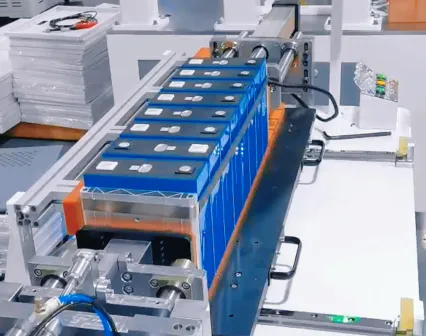

When it comes to packaging lithium battery modules, the choice of strapping material—PET (polyester) straps or steel straps—plays a critical role in ensuring product safety, efficiency, and cost-effectiveness. Each option has its unique properties, making the decision dependent on your specific application and requirements. This article examines the key factors to consider when selecting between PET straps and steel straps for lithium battery module bundling.

PET Straps: Lightweight and Durable

Key Advantages:

High Tensile Strength: PET straps provide excellent strength for securing medium to heavy loads, making them suitable for lithium battery modules.

Elasticity: Unlike steel, PET straps have a slight stretch, allowing them to absorb impacts during transport without breaking.

Corrosion Resistance: PET straps do not rust, ensuring the lithium battery modules remain clean and uncontaminated.

Lightweight: PET straps are easier to handle, reducing the labor effort required for packaging.

Cost-Effective: PET straps are generally more affordable than steel straps and have a lower environmental footprint due to recyclability.

Best For: Applications where the packaging does not face extreme external pressure, such as moderate transport distances and indoor storage.

Steel Straps: Unmatched Strength and Stability

Key Advantages:

Superior Strength: Steel straps can withstand extremely high tension, ensuring maximum stability for heavy or dense lithium battery modules.

Minimal Stretching: Steel straps maintain their shape, providing a tight, secure hold, even under heavy loads.

Fire Resistance: Steel straps are resistant to high temperatures, making them ideal for environments where fire safety is a concern.

Limitations: Steel straps can rust, increasing the risk of contamination. Additionally, they are heavier and can pose safety risks during handling due to sharp edges.

Best For: Heavy-duty packaging, long-distance transportation, or applications where maximum security is critical.

Choosing the Right Strapping Material

The decision between PET straps and steel straps depends on several factors:

Weight of the Battery Module: PET straps are sufficient for lightweight to medium loads, while steel straps are preferred for heavy loads.

Environmental Conditions: Choose PET straps for humid environments to avoid rust or steel straps for areas where extreme temperatures are expected.

Cost and Sustainability: If budget and eco-friendliness are priorities, PET straps are the better choice.

Transport Risks: For long-distance shipping with higher risk of impacts, steel straps provide greater durability.

SUNKA LEAD Offers Tailored Solutions

At SUNKA LEAD, we provide high-quality packaging solutions for lithium battery modules, including strapping machines compatible with both PET and steel straps. Our team can guide you in selecting the best strapping material to suit your packaging requirements. Contact us today to optimize your battery packaging process with reliable and efficient solutions.