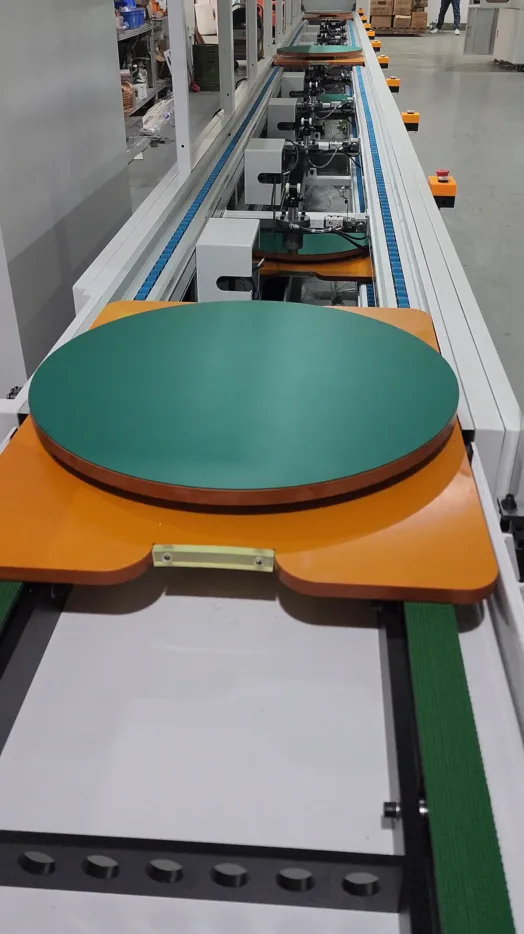

What is a Semi-Automatic Conveyor Belt for Cylindrical & Prismatic Battery Production?

A semi-automatic conveyor belt is a specialized transport system designed to streamline the production of cylindrical and prismatic lithium batteries. It serves as an integral part of modern battery manufacturing, bridging the gap between manual and fully automated processes. This equipment facilitates the efficient movement and handling of battery components, ensuring precision and consistency in production while maintaining flexibility for manufacturers.

Key Advantages of Semi-Automatic Conveyor Belts

1. Enhanced Production Efficiency

The semi-automatic conveyor belt significantly improves the efficiency of production lines by combining manual oversight with automated transport systems. Operators can focus on critical tasks while the conveyor ensures the smooth transfer of batteries between different production stages. This hybrid approach boosts productivity without requiring full automation investments.

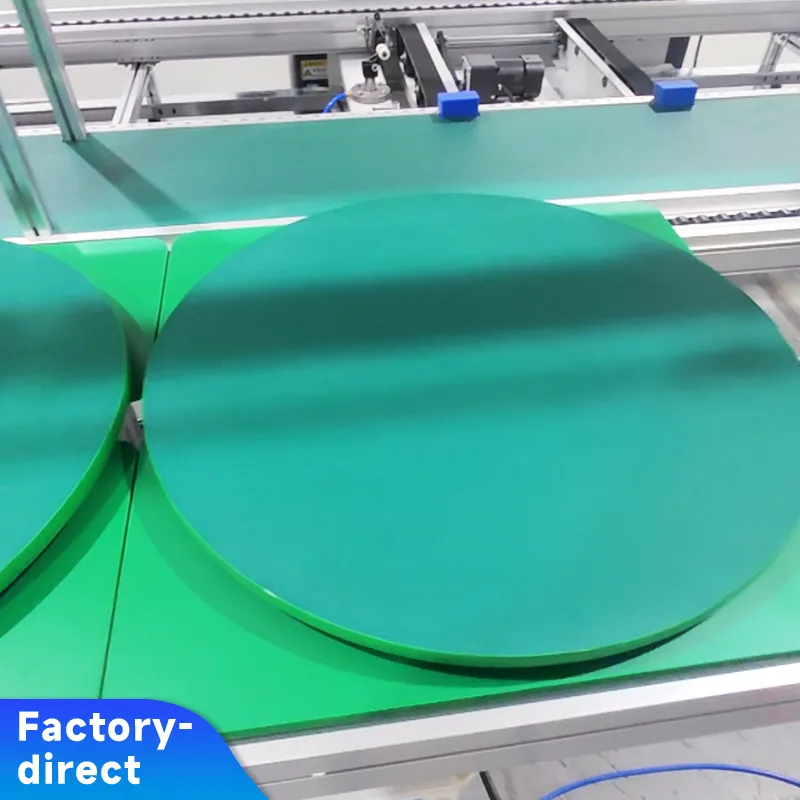

2. Support for Cylindrical and Prismatic Batteries

The conveyor is designed to handle multiple battery types, including cylindrical and prismatic cells. This versatility makes it an ideal choice for manufacturers catering to diverse markets, such as electric vehicles, energy storage systems, and consumer electronics. Adjustable settings allow the conveyor to accommodate different battery sizes and shapes seamlessly.

3. Stable and Secure Transportation

The system includes specialized clamps and adjustable settings to ensure batteries remain stable during transportation. Whether the product is cylindrical or prismatic, the conveyor prevents slipping, dislodging, or damage, reducing waste and improving yield rates.

4. Cost-Effective Semi-Automation

For manufacturers not ready to transition to fully automated systems, a semi-automatic conveyor belt offers an economical alternative. It reduces manual labor requirements while still allowing for operator control in critical areas. This cost-effective solution bridges the gap between traditional manual lines and advanced automation.

5. Flexible and Scalable Design

The conveyor belt’s modular structure allows manufacturers to customize and expand their production line layouts. Whether adapting to space constraints or scaling operations, the equipment provides the flexibility needed for dynamic production environments.

6. Improved Workflow Consistency

Semi-automatic conveyor belts ensure a steady and predictable workflow, minimizing bottlenecks and reducing the chances of human error. Consistent transport intervals enhance overall production line efficiency and maintain a smooth operation.

7. Integrated Quality Monitoring

Some semi-automatic systems include basic monitoring capabilities, enabling manufacturers to track key parameters and identify issues early in the production process. This feature ensures product consistency and supports quality assurance goals.

Why Choose a Semi-Automatic Conveyor Belt?

A semi-automatic conveyor belt is the perfect solution for manufacturers seeking to optimize their battery production lines without committing to full automation. With its balance of efficiency, precision, and affordability, it is well-suited for producing high-quality cylindrical and prismatic batteries.

Contact us today to learn how our semi-automatic conveyor systems can enhance your battery production operations and drive your business forward.