In the rapidly evolving realm of lithium - battery manufacturing, every step in the production process is crucial. Among these, the lithium - battery polarity detection station stands out as a cornerstone of quality control and safety assurance.

Ensuring Battery Performance

The correct polarity is fundamental for a lithium - battery's proper functioning. When the polarity is incorrect, the battery's internal electrochemical reactions are disrupted. This can lead to a significant decrease in battery capacity, shorter lifespan, and reduced overall performance. For example, in an electric vehicle, a mis - polarized battery could result in a sudden drop in power, reduced driving range, and potential damage to the vehicle's electrical system. A well - functioning polarity detection station catches these issues early, ensuring that only batteries with the correct polarity move forward in the production process, thus maintaining high - quality standards.

Preventing Safety Hazards

Safety is a top priority in lithium - battery production. Incorrectly polarized batteries pose serious safety risks. During charging or discharging, they can experience overheating, short - circuits, or even explosion. These hazards not only endanger the integrity of the battery products but also put the lives of consumers and production workers at risk. By installing a reliable polarity detection station in the production line, manufacturers can identify and eliminate mis - polarized batteries, significantly reducing the likelihood of safety - related incidents.

Enhancing Production Efficiency

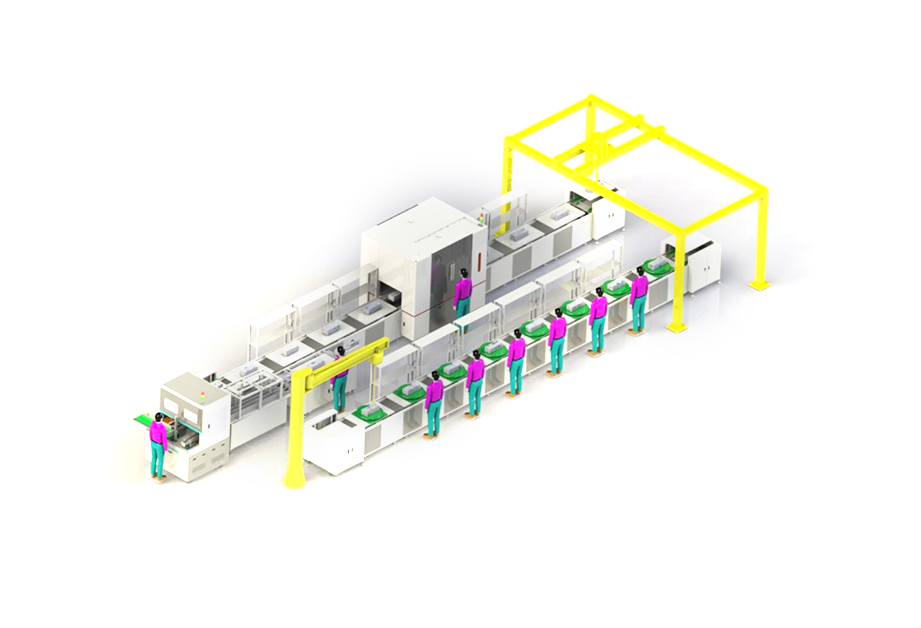

From a production perspective, the polarity detection station streamlines the manufacturing process. Early detection of polarity issues means that defective batteries are removed from the production line promptly. This reduces the time and resources wasted on further processing of faulty products. It also minimizes the need for rework, which can be both time - consuming and costly. For instance, if a mis - polarized battery goes undetected until the final assembly stage, the entire assembly may need to be disassembled and the battery replaced, leading to production delays. A fast and accurate polarity detection station helps keep the production line running smoothly, increasing overall efficiency.

Protecting Brand Reputation

In today's competitive market, brand reputation is everything. A single safety incident or a batch of low - quality batteries can severely damage a company's image. By implementing a robust polarity detection system, manufacturers can ensure that their products are safe and reliable. This, in turn, builds trust among consumers and partners. A positive brand reputation can lead to increased customer loyalty, higher market share, and ultimately, greater business success.

In conclusion, the lithium - battery polarity detection station is an indispensable part of the lithium - battery production process. It plays a vital role in ensuring battery performance, preventing safety hazards, enhancing production efficiency, and protecting brand reputation. As the demand for lithium - batteries continues to grow, investing in high - quality polarity detection stations is not just an option but a necessity for manufacturers aiming to stay ahead in the game.