Introduction

As energy storage demand rises globally, efficient battery production is critical. Battery assembly machines play a pivotal role in creating high-quality battery packs for industries like electric vehicles (EVs), energy storage systems (ESS), and electronics.

What Are Battery Assembly Machines?

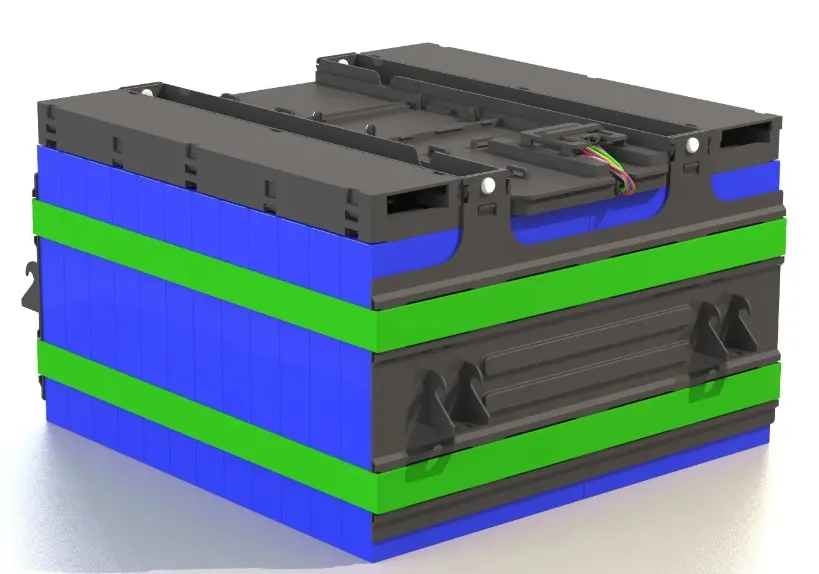

Battery assembly machines automate the production of battery packs, ensuring precision and consistency. Key functions include spot welding, stacking, labeling, side gluing, and testing. These machines cater to prismatic, cylindrical, and pouch battery types, offering manufacturers flexibility for various applications.

Applications of Battery Assembly Machines

Electric Vehicles (EVs): As the automotive industry shifts to sustainability, EV battery packs are in high demand. Assembly machines ensure scalable production and meet rigorous quality standards.

Energy Storage Systems (ESS): Battery assembly machines are vital for producing energy storage solutions used in residential and commercial applications, particularly for renewable energy storage.

Power Tools and Electronics: High-quality battery packs for portable devices and tools depend on the efficiency and precision of these machines.

Conclusion

Battery assembly machines are transforming the way energy storage solutions are produced. Their precision and efficiency drive advancements in sustainable energy and portable power solutions.