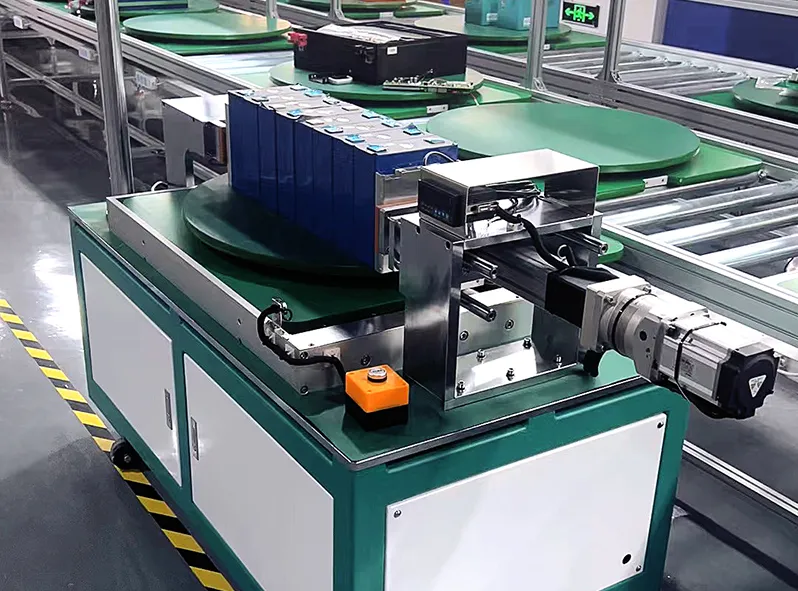

In the manufacturing of battery modules, stability and safety are paramount. The Battery Module Compression and Steel Band Strapping Station is a vital part of the production process, ensuring that modules are securely assembled and prepared for various applications. This station combines precision engineering with advanced technology to enhance the reliability of battery modules.

Function Description

The primary function of the Battery Module Compression and Steel Band Strapping Station is to compress battery modules and tightly secure them to end plates using steel bands. This process ensures a robust connection, enhancing the overall structural stability and safety of the module.

Operation Process

Placement: Begin by placing the battery module and the end plates onto the compression machine.

Compression: Activate the compression machine, which applies pressure to bring the module and end plates together at a precise distance.

Steel Band Strapping: Wrap a steel band around the compressed module and ensure it is tightly secured, firmly connecting the module with the end plates.

Completion: Reset the compression machine, finalizing the steel band strapping operation.

Technical Advantages

Enhanced Structural Stability: The compression operation ensures a tight connection between the battery module and the end plates, significantly improving the product's structural stability.

Improved Safety: The use of steel bands provides an additional layer of security, preventing the module from loosening or getting damaged during transportation or usage.

Reliability for Demanding Applications: By securing modules with steel bands, manufacturers can deliver battery modules that meet the rigorous demands of modern energy storage and electric vehicle applications.

Why It Matters

The combination of compression and steel band strapping is essential for maintaining the integrity of battery modules. Without proper stabilization, modules could experience internal stress, leading to performance issues or safety risks. This station not only prevents such problems but also contributes to the longevity and reliability of the modules, ensuring they meet the highest quality standards.

Future Outlook

As the demand for high-performance battery modules continues to grow in industries such as electric vehicles and renewable energy, advancements in compression and strapping technology are expected. Future iterations of this station may incorporate automation, AI-based tension control, and real-time monitoring systems to further optimize the process.

Conclusion

The Battery Module Compression and Steel Band Strapping Station plays a critical role in ensuring the structural integrity and safety of battery modules. By combining precise compression with secure steel banding, this station meets the industry's stringent requirements for quality and reliability, making it an indispensable part of the battery production process.