In the realm of modern energy storage systems, especially those centered around lithium - ion batteries, the Battery Management System (BMS) plays a pivotal role. As the "brain" of a battery system, the BMS is responsible for ensuring the safe, efficient, and long - lasting operation of batteries. To guarantee the proper functionality of the BMS, a specialized piece of equipment - the BMS Tester - has emerged as an indispensable asset in the battery industry.

A BMS tester is a sophisticated device designed to evaluate, verify, and optimize the performance of Battery Management Systems. It serves as a diagnostic tool that allows manufacturers, technicians, and researchers to thoroughly assess the capabilities and functions of a BMS. By subjecting the BMS to a series of comprehensive tests, the tester can identify potential issues, measure performance metrics, and ensure compliance with industry standards.

2. Key Functions and Features

2.1 Electrical Parameter Testing

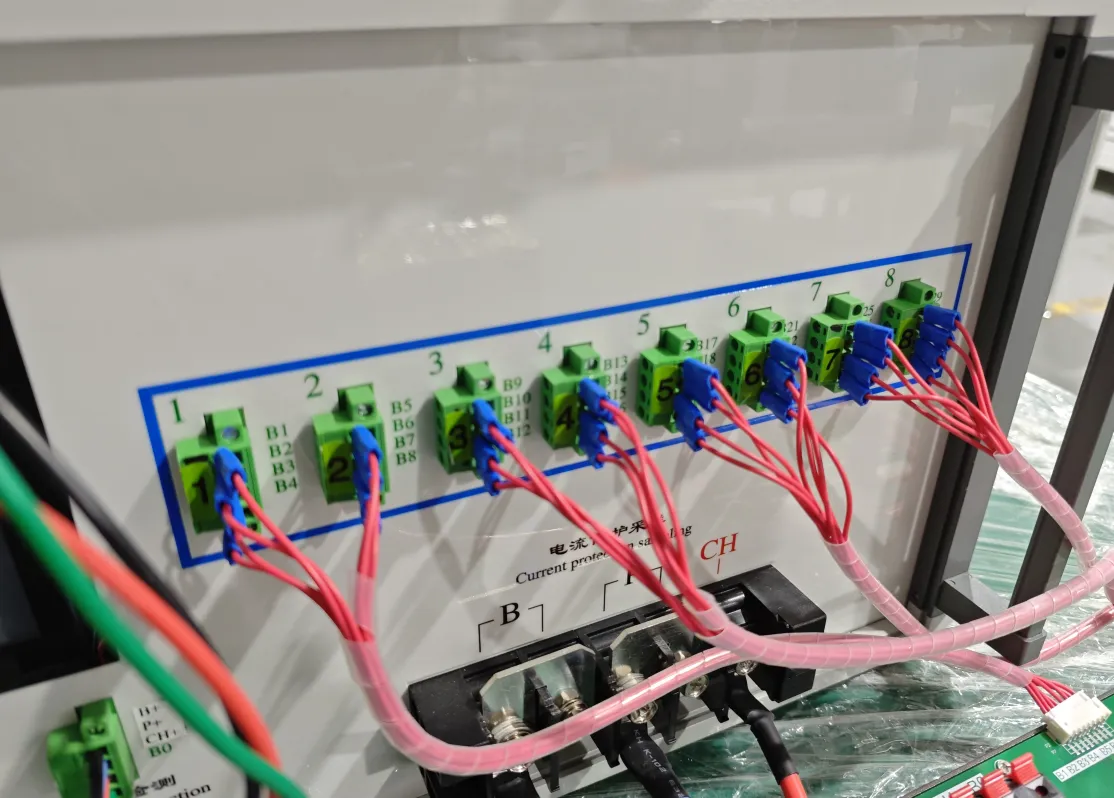

Voltage and Current Measurement: One of the fundamental functions of a BMS tester is to accurately measure the voltage and current levels within the battery system. This includes monitoring the voltage of individual battery cells as well as the overall battery pack voltage. Precise current measurement helps in determining the charge and discharge rates, which are critical for assessing the BMS's ability to manage power flow efficiently. For example, in an electric vehicle battery pack, the BMS tester can measure the current draw during acceleration and the charging current during recharging, ensuring that the BMS can handle these dynamic power demands.

Internal Resistance Detection: Measuring the internal resistance of battery cells is another important aspect. An increase in internal resistance can indicate battery degradation or potential faults. The BMS tester can precisely measure this parameter, allowing the BMS to be adjusted or the battery cells to be replaced if necessary.

2.2 Communication Protocol Testing

CAN Bus and Other Protocols: Most modern BMSs communicate with other components in the system, such as the vehicle's control unit or an energy storage system's monitoring system, using communication protocols like CAN (Controller Area Network) bus. The BMS tester can simulate different communication scenarios, sending and receiving data packets to verify that the BMS can communicate effectively. It can also detect communication errors, latency issues, and ensure proper data integrity. For instance, in a large - scale energy storage installation, seamless communication between the BMS and the grid - connected inverter is crucial, and the BMS tester can ensure that the BMS adheres to the required communication protocols.

2.3 Protection Function Testing

Over - Voltage, Over - Current, and Over - Temperature Protection: The BMS is equipped with various protection mechanisms to safeguard the battery from damage. The BMS tester can simulate over - voltage, over - current, and over - temperature conditions to test the effectiveness of these protection functions. For example, it can gradually increase the voltage applied to the battery pack to see at what point the BMS triggers the over - voltage protection and cuts off the charging circuit, ensuring the safety and longevity of the battery cells.

3. Applications

3.1 Battery Manufacturing

Quality Control: In battery manufacturing plants, BMS testers are used to conduct rigorous quality control checks on every BMS produced. This ensures that only BMSs with reliable performance and functionality are integrated into battery packs. By catching defective BMSs early in the production process, manufacturers can reduce the risk of costly recalls and improve the overall quality of their products.

3.2 Electric Vehicle Industry

Performance Optimization: Electric vehicles rely heavily on BMSs to manage their high - voltage battery packs. BMS testers are used during the development and testing phases of electric vehicles to optimize the BMS's performance. This includes fine - tuning the charge and discharge algorithms, ensuring proper communication with the vehicle's powertrain, and enhancing the overall safety and efficiency of the vehicle's battery system.

3.3 Energy Storage Systems

Reliability Assurance: For grid - connected energy storage systems, the reliability of the BMS is crucial for stable energy storage and power supply. BMS testers are used to periodically test and maintain the BMSs in these systems, ensuring that they can operate effectively under various environmental conditions and power demands.

4.1 Compatibility

BMS Types and Protocols: Ensure that the BMS tester is compatible with the types of BMSs you are working with. Different manufacturers may use different BMS architectures and communication protocols, so it's essential to select a tester that can support all the necessary standards.

4.2 Functionality

Testing Capabilities: Consider the specific testing functions you need. If you are mainly concerned with electrical parameter testing, look for a tester with high - precision measurement capabilities. If communication protocol testing is a priority, choose a tester that can handle a wide range of communication protocols and simulate complex communication scenarios.

4.3 User - Friendliness

Interface and Operation: A user - friendly BMS tester with an intuitive interface and easy - to - understand operation procedures can save time and effort. Look for testers with clear displays, simple menu navigation, and helpful error messages.

In conclusion, the BMS tester equipment is a vital component in the battery management ecosystem. Its ability to test and validate the performance of BMSs is essential for ensuring the safety, efficiency, and reliability of modern energy storage systems. Whether in battery manufacturing, electric vehicle development, or energy storage applications, choosing the right BMS tester can significantly impact the quality and success of these endeavors.