In the dynamic landscape of modern industrial operations, the multispeed chain stands as an unsung hero, quietly yet powerfully driving the wheels of production and logistics. This remarkable conveyor system component has brought about a paradigm shift in the way products are transported, assembled, and sorted across various manufacturing processes.

Decoding the Multispeed Chain

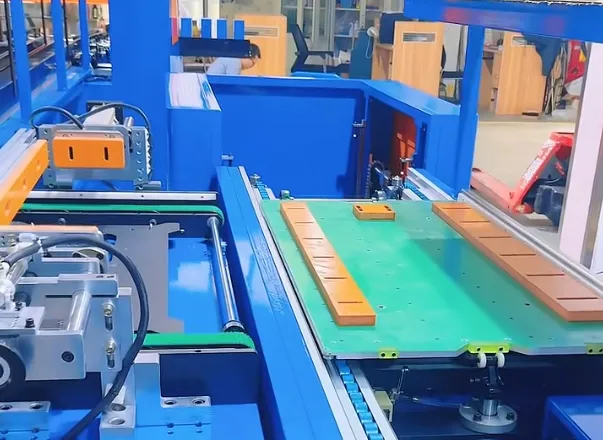

At its core, a multispeed chain is a specialized conveyor chain engineered to operate at variable speeds. Comprising a sequence of interconnected links, typically crafted from robust materials like steel or high - performance plastics, these chains are set in motion by sprockets that are linked to motors or other power - generating sources. The defining characteristic of the multispeed chain lies in its capacity to adapt its speed in accordance with the specific demands of the production workflow.

The Inner Workings of Multispeed Chains

The functionality of a multispeed chain is a harmonious blend of mechanical and electrical elements. Motors supply the necessary power to the sprockets, which then propel the chain forward. The speed regulation of the chain is achieved through a variety of methods. A prevalent approach involves the use of variable - frequency drives (VFDs). These VFDs fine - tune the frequency of the electrical power delivered to the motor, enabling precise control over the motor's rotational speed and, by extension, the speed of the chain.

For instance, in a sophisticated electronics manufacturing facility, different phases of the production process may necessitate distinct speeds. The meticulous placement of tiny components at the initial stages demands a slower, more deliberate pace to guarantee accuracy. In contrast, the final stages of product testing and packaging can be executed at an accelerated speed. The multispeed chain effortlessly caters to these changing requirements, smoothly transitioning between different speeds as products progress along the production line.

The Multifaceted Advantages of Multispeed Chains

Unmatched Flexibility

One of the most notable strengths of multispeed chains is their unparalleled flexibility. They can be seamlessly incorporated into existing production lines and tailored to meet the diverse needs of different manufacturing operations. This adaptability empowers manufacturers to optimize their production processes, enhance efficiency, and minimize downtime.

Enhanced Productivity

By facilitating different speeds at various stages of production, multispeed chains significantly boost overall productivity. Operations that demand a high level of precision can be carried out at a slower, more controlled speed, reducing the likelihood of errors. Meanwhile, tasks that are less intricate can be completed at a faster pace, thereby increasing the output of the production line.

Cost - Effective Solution

Multispeed chains also offer a cost - effective solution for industrial operations. Their ability to adapt to a wide range of production requirements means that manufacturers can avoid the need to invest in multiple conveyor systems for different tasks. This not only cuts down on equipment costs but also reduces maintenance and operational expenses.

Diverse Applications of Multispeed Chains

Multispeed chains find extensive use across a multitude of industries. In the automotive sector, they are employed in assembly lines to transport heavy car components such as engines, transmissions, and body frames. The ability to adjust the chain's speed ensures that these large and intricate parts are handled with care during the assembly process.

In the food and beverage industry, multispeed chains play a crucial role in tasks such as bottling, canning, and packaging. Different stages of these processes, such as filling and labeling, require specific speeds to ensure product quality and integrity.

The electronics industry, too, relies heavily on multispeed chains. From the assembly of delicate printed circuit boards to the final packaging of consumer electronics, multispeed chains are instrumental in ensuring the seamless and efficient operation of production lines.

In summary, the multispeed chain is an indispensable component of modern industrial operations. Its ability to operate at variable speeds provides the flexibility, productivity, and cost - savings that are essential for businesses striving to thrive in today's competitive global marketplace. As technology continues to evolve, the future of multispeed chains holds even more promise, with the potential for further innovation and expanded applications.