In the rapidly evolving battery production industry, precision and efficiency are paramount. One key aspect of this process is battery sorting, which directly impacts the performance, safety, and longevity of battery packs. A fully automated Battery Sorting Machine, especially one that sorts based on OCV (Open Circuit Voltage) and IR (Internal Resistance), is a game changer in modern battery manufacturing. Here’s why investing in such a system can elevate your production line.

1. Enhanced Precision in Battery Sorting

Sorting batteries based on their OCV and IR ensures that only batteries with similar characteristics are grouped together. This level of precision helps eliminate inconsistencies that could affect the overall performance of a battery pack. Batteries with similar voltage and internal resistance behave similarly under load, making them ideal for use in the same pack.

By automating this process, the sorting machine can measure each battery’s OCV and IR quickly and accurately, improving the precision of the final product and reducing the risk of performance issues such as capacity degradation or safety concerns.

2. Increased Efficiency and Speed

Manual sorting is time-consuming and prone to human error, often slowing down the production process. A fully automated battery sorting machine accelerates this task by quickly measuring the OCV and IR of thousands of batteries in a fraction of the time it would take manually. This significantly boosts throughput, enabling manufacturers to meet high-demand production targets without compromising on quality.

With automation, the sorting process is continuous, eliminating bottlenecks and optimizing workflow on the production line.

3. Improved Battery Performance and Reliability

Batteries sorted by OCV and IR are more likely to work harmoniously when integrated into a battery pack. Consistent OCV levels ensure that all cells in a pack charge and discharge at similar rates, preventing issues such as overcharging or deep discharging. Likewise, batteries with similar IR values will have similar internal resistances, leading to more uniform heat generation and better thermal management within the pack.

This precision ultimately enhances the reliability and performance of the final battery pack, whether for electric vehicles, energy storage systems, or consumer electronics.

4. Reduced Risk of Failures and Rework

By accurately sorting batteries based on their OCV and IR, manufacturers can avoid using mismatched cells that could lead to performance failures or safety issues. Batteries with irregular IR or OCV values can cause imbalance in the battery pack, leading to premature failure, capacity loss, or even catastrophic events like thermal runaway. Sorting with an automated system minimizes the chances of such failures and reduces the need for costly rework or replacements.

5. Cost Savings and Long-Term ROI

While investing in a fully automated sorting system may seem like a significant upfront cost, the long-term benefits far outweigh the initial investment. By increasing sorting accuracy, improving battery pack reliability, and reducing failures, manufacturers save on labor costs and reduce wastage due to faulty or mismatched batteries. Over time, the system pays for itself through enhanced production efficiency and lower maintenance and rework costs.

6. Easy Integration with Existing Production Lines

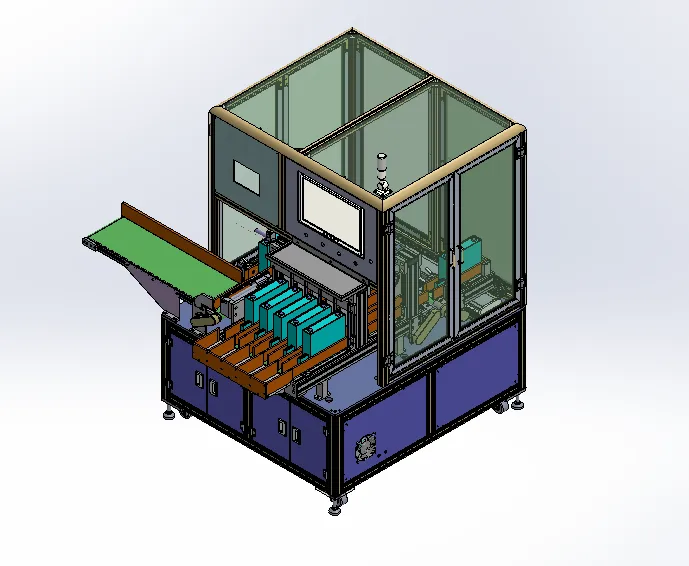

SUNKA LEAD’s automated battery sorting machines are designed to easily integrate into existing battery production lines. These machines feature user-friendly interfaces, adaptable configurations, and real-time data tracking, allowing manufacturers to seamlessly incorporate them into their current setup. The integration ensures that the sorting process is fully automated without requiring major overhauls to the entire production system.

Conclusion: The Future of Battery Sorting

In the competitive world of battery production, precision, speed, and reliability are key to success. A fully automated battery sorting machine that classifies batteries based on OCV and IR offers unparalleled benefits in terms of performance, efficiency, and cost savings. SUNKA LEAD’s state-of-the-art sorting machines are engineered to optimize your battery production process, ensuring that each battery pack is built to last and perform at its best.

Contact us today to learn more about how our automated sorting technology can improve your battery manufacturing process.