A Cylindrical Battery Double-Sided Spot Welding Fixture is a specialized tool designed to hold and secure lithium-ion battery packs, particularly for cylindrical batteries such as the 21700 series, during the spot welding process. This fixture is part of an automated Spot Welding Machine and is essential for ensuring accurate, consistent, and reliable welding of battery terminals and connecting plates. The fixture ensures that the battery cells are held firmly in place while welding, reducing the risk of misalignment, damaging the battery, or inconsistent weld quality.

Key Features of the Cylindrical Battery Spot Welding Fixture

Double-Sided Welding Support

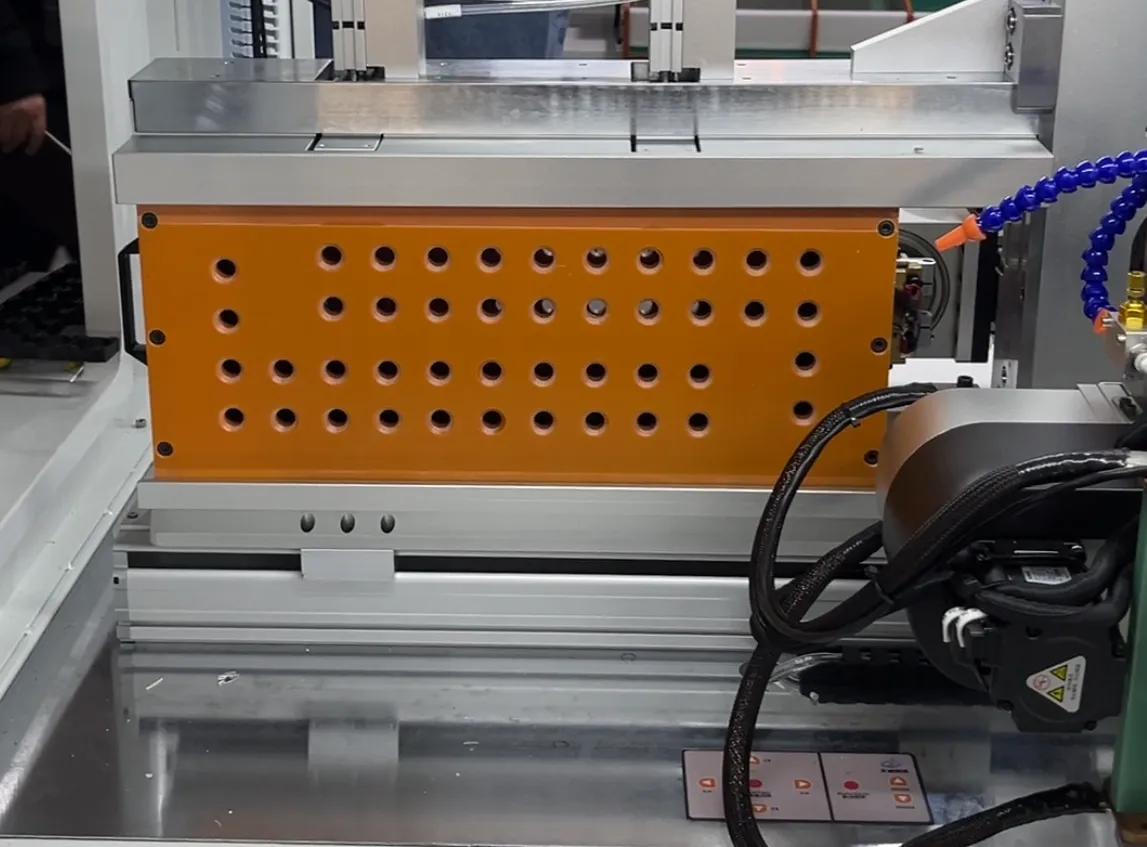

The fixture is designed for both single-side and double-side welding, making it versatile for various welding configurations. It is optimized for 21700 lithium-ion batteries, commonly used in electric vehicles, energy storage systems, and power tools.Precise Alignment and Stability

The fixture ensures accurate positioning of battery cells during the welding process. Its robust design minimizes movement or shifting of the batteries, ensuring precise welds every time.High Durability and Reliability

Built with high-quality materials, the fixture is designed for long-term use. It withstands the intense forces of welding without degrading, providing consistent performance in high-volume production lines.Automation Compatibility

This fixture is designed to be used with automatic spot welding machines, allowing for efficient, high-speed production of battery packs. It streamlines the entire assembly process by reducing manual labor and ensuring uniform weld quality.Customizable for Different Battery Types

In addition to 21700 cylindrical batteries, this fixture can be customized to accommodate other battery sizes, making it adaptable for various production needs.

How Does It Work?

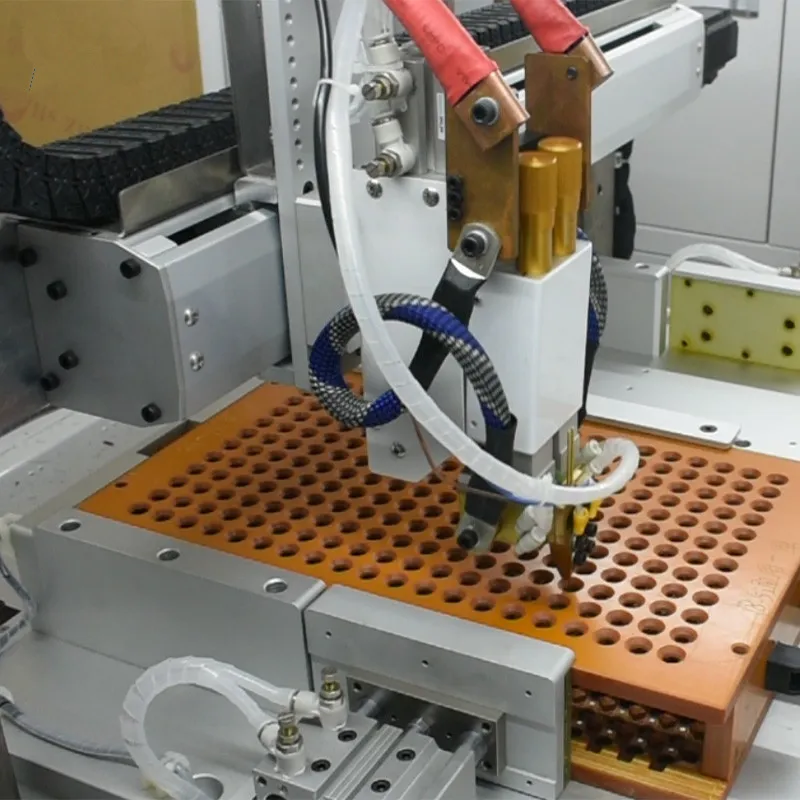

Positioning and Securing the Battery Cells

The cylindrical battery is placed into the fixture. The design ensures that the battery terminals and connections are precisely aligned for spot welding.Automated Spot Welding

The automatic spot welding machine uses the fixture to apply the welding process. The double-sided design allows both positive and negative terminals to be welded simultaneously, ensuring high welding efficiency and consistency.Testing and Quality Control

After welding, the fixture ensures that all welded connections are intact and reliable, reducing the risk of poor-quality or inconsistent welds.Removal and Collection

After successful welding, the battery cells are removed from the fixture and are ready for further assembly or testing.

Benefits of Using a Cylindrical Battery Spot Welding Fixture

Increased Welding Precision

With accurate positioning and secure holding, the fixture ensures high-precision welds, which is critical in ensuring battery safety and longevity.Enhanced Production Efficiency

By automating the process, this fixture reduces manual handling, leading to faster production times and lower labor costs.Improved Battery Safety

With a secure hold and precise alignment, the risk of damaging the battery during the welding process is minimized, improving the overall safety of the battery pack.Consistent Weld Quality

The fixture ensures that every weld is uniform and strong, improving the consistency of the final battery pack and reducing the potential for defects.Adaptable for Multiple Battery Types

This fixture can be used for various cylindrical battery sizes and types, including 21700, 18650, and other popular lithium-ion battery sizes.

Applications of Cylindrical Battery Spot Welding Fixtures

Electric Vehicles (EVs): Used for spot welding battery packs in electric vehicles, ensuring high-quality and reliable battery connections.

Energy Storage Systems (ESS): Perfect for large-scale battery packs used in solar energy storage and grid systems.

Power Tools: Ensures precise welding for battery packs used in cordless power tools, improving performance and reliability.

Consumer Electronics: Ideal for precision welding of smaller lithium-ion batteries used in devices like laptops, tablets, and smartphones.

Important Considerations

Battery Compatibility: Ensure the fixture is compatible with the battery sizes you plan to use. Customizations are often available to support different battery configurations.

Machine Integration: This fixture is designed to integrate seamlessly with automated welding machines, so make sure your welding system is compatible.

Quality Control: Regular maintenance and testing of the fixture are essential to ensure that the alignment and weld quality are consistently high.

Conclusion

The Cylindrical Battery Double-Sided Spot Welding Fixture is a critical component for achieving precise, high-quality welds in the production of lithium-ion battery packs. Whether you're working with 21700 batteries or other cylindrical cell types, this fixture helps streamline your production process, improve welding efficiency, and enhance battery safety. By integrating it with automated spot welding machines, manufacturers can ensure consistent, reliable, and cost-effective battery assembly.

At SUNKA LEAD, we provide advanced battery welding solutions designed to meet the demands of modern production lines. Our customizable fixtures and welding equipment are engineered to ensure the best possible results in your battery assembly process.

For more information on how our battery welding fixtures can optimize your production, contact us today!