In the world of battery management, precision and functionality are key. Battery protection board testers are essential tools for ensuring that battery packs operate safely and efficiently. Two common types of testers are the 1-32 Series Power Battery Protection Board Tester and the 1-24 Series Protection Board Tester. While both serve the same purpose of testing and validating the performance of protection boards (BMS), there are key differences in their capabilities. In this article, we’ll explore the differences between these two models and help you determine which is right for your battery testing needs.

1. What is a Battery Protection Board Tester?

A battery protection board tester is used to evaluate the functionality of a Battery Management System (BMS). These systems protect batteries by monitoring the voltage of individual cells, ensuring proper cell balancing, and preventing overcharging, over-discharging, and overheating. Protection board testers simulate various charging and discharging conditions to ensure that the BMS functions correctly under real-world conditions.

2. The Difference in Series Capacity: 1-32 vs 1-24

The primary difference between the 1-32 Series Power Battery Protection Board Tester and the 1-24 Series Protection Board Tester is the number of series connections they can handle. Here’s how each model differs:

1-32 Series Power Battery Protection Board Tester: This tester is designed to support up to 32 series-connected cells in a battery pack. It is ideal for high-capacity battery packs, such as those used in electric vehicles (EVs), large energy storage systems, and industrial applications. The 1-32 Series allows manufacturers to test larger battery packs with more series-connected cells, making it versatile for more demanding testing scenarios.

1-24 Series Protection Board Tester: This model is designed to support up to 24 series-connected cells in a battery pack. It’s suitable for testing medium-capacity battery packs used in applications such as consumer electronics, small-scale energy storage systems, and some electric vehicles. The 1-24 Series is ideal for users who do not need the extra capacity offered by the 1-32 Series but still require high-quality protection board testing.

3. Application Differences

1-32 Series Tester: This tester is typically used in industries that require testing for larger, more complex battery packs. This includes electric vehicle (EV) manufacturers, large-scale energy storage, and solar power storage systems, where the battery packs often exceed 24 cells in series. It offers the capacity to handle higher voltage and larger battery configurations.

1-24 Series Tester: The 1-24 Series is ideal for manufacturers working with smaller battery packs, such as those found in consumer electronics, portable devices, and smaller energy storage solutions. These systems are often simpler, with fewer series-connected cells, making the 1-24 tester a more affordable and appropriate choice for these applications.

4. Testing Features and Capabilities

Both the 1-32 Series and 1-24 Series protection board testers come with essential testing features such as:

Overcharge and Over-discharge Protection Testing

Short Circuit Detection

Temperature Control and Thermal Runaway Prevention

Cell Balancing and Voltage Monitoring

However, the 1-32 Series often comes with more advanced features to accommodate the larger packs, such as higher voltage thresholds, greater power capacity, and more detailed cell-level monitoring. On the other hand, the 1-24 Series provides all the essential testing functions but is more compact and budget-friendly.

5. Why Choose SUNKA LEAD’s Battery Protection Board Testers?

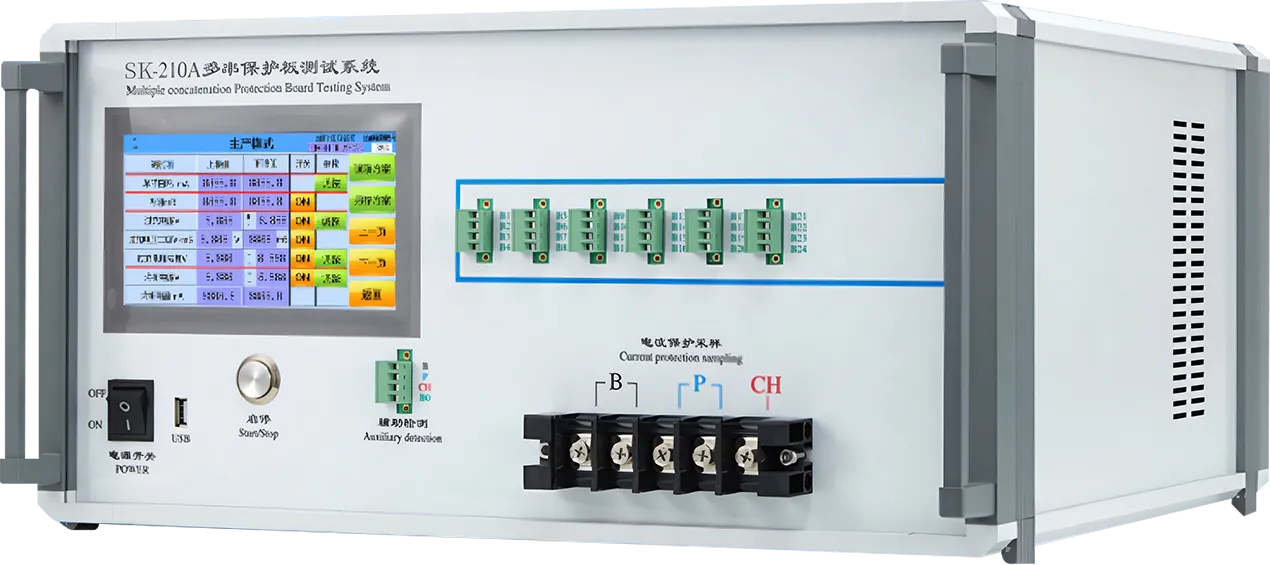

At SUNKA LEAD, we provide high-performance battery protection board testers that deliver precise and reliable results. Whether you need to test large, multi-cell configurations with the 1-32 Series or work with smaller packs using the 1-24 Series, our testers ensure that your protection boards are working as expected, preventing battery failures and safety hazards. With features like real-time data monitoring, automated testing, and user-friendly interfaces, SUNKA LEAD’s testers help manufacturers maintain high standards of safety and performance.

Conclusion: Choosing the Right Tester for Your Battery Pack

The 1-32 Series Power Battery Protection Board Tester and the 1-24 Series Protection Board Tester are both essential tools in ensuring the safety and performance of battery packs. The key difference lies in the number of series-connected cells they support. If you’re working with larger, high-capacity battery packs, the 1-32 Series is your best option. For smaller, medium-capacity packs, the 1-24 Series is a cost-effective and reliable choice.

Contact us today to learn more about how SUNKA LEAD’s battery protection board testers can support your battery testing needs and help you ensure the safety of your battery packs.