Lithium-ion batteries are widely used in everything from smartphones to electric vehicles and energy storage systems. While these batteries offer high energy density and longevity, they can also pose risks, including the potential for explosions. But what exactly causes these explosions, and how can we prevent them? This article will explore the factors that contribute to lithium battery explosions and how safety measures are implemented to protect both manufacturers and consumers.

Common Causes of Lithium Battery Explosions

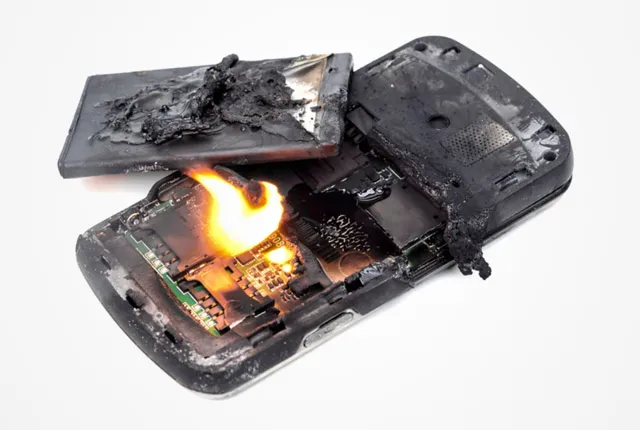

Thermal Runaway: One of the most common causes of battery explosions is thermal runaway. This occurs when the battery's temperature increases rapidly due to internal faults, like a short circuit or overcharging. The rising temperature can cause a chemical reaction inside the battery, releasing gases and potentially leading to a fire or explosion.

Physical Damage: Dropping a lithium battery or subjecting it to physical damage can lead to internal short circuits. If the protective casing is compromised, it can lead to dangerous outcomes, such as an explosion or fire.

Overcharging or Overdischarging: Overcharging a lithium battery can cause excessive heat buildup, while overdischarging may lead to instability in the battery's chemistry. Both scenarios increase the risk of dangerous reactions within the cell.

Poor Battery Design or Manufacturing Defects: Faulty designs or defects during manufacturing, such as improper sealing or defective components, can compromise the battery's safety. These issues can lead to overheating, leakage, or even catastrophic failure.

Safety Measures in Lithium Battery Production

To address these risks, manufacturers and battery producers implement a variety of safety measures throughout the design and production process.

Battery Management Systems (BMS): A BMS is crucial in monitoring and controlling the voltage, current, and temperature of lithium batteries. By preventing overcharging, overdischarging, and overheating, BMS helps ensure the safe operation of the battery.

Cell Design Improvements: Advances in battery design, such as the use of safer materials and improved separators, have made lithium-ion batteries more stable. Some batteries are now equipped with pressure-release valves that help release gases in the event of overheating, preventing explosions.

Quality Control in Manufacturing: Rigorous quality control during production is key to preventing defective batteries from reaching consumers. Testing for internal short circuits, using protective films, and ensuring proper sealing can reduce the risk of failure.

Advanced Charging and Discharging Technology: Modern charging systems are designed to stop charging once the battery reaches full capacity, and to safely discharge the battery to avoid over-discharging. These technologies help ensure the longevity and safety of lithium batteries.

The Future of Lithium Battery Safety

As demand for lithium-ion batteries continues to grow, especially with the rise of electric vehicles and renewable energy storage, research and development into safer battery technologies is accelerating. Companies are working on new chemistries, such as solid-state batteries, which promise to offer higher energy density and greater safety compared to traditional lithium-ion batteries.

At SUNKA LEAD, we prioritize safety in every aspect of battery production. Our automated production lines are designed to improve the efficiency and safety of lithium battery manufacturing, ensuring that every battery produced meets high safety standards. From laser welding machines to battery testing systems, we offer a range of solutions to support safe, high-quality battery production.

Conclusion

Lithium battery explosions, while rare, can happen under certain circumstances. Understanding the causes and implementing safety measures is crucial in reducing these risks. With advancements in technology and manufacturing practices, the safety of lithium-ion batteries continues to improve, making them a reliable and safe energy source for the future.

If you're involved in battery production, it’s essential to invest in reliable equipment and ensure stringent safety protocols are followed. At SUNKA LEAD, we’re committed to providing cutting-edge solutions that enhance both the efficiency and safety of battery manufacturing. Reach out today to learn how our innovative equipment can support your battery production process.