OCV (Open Circuit Voltage) refers to the voltage of a battery when it is not connected to any load or external circuit. It provides important information about the battery's state of charge (SOC) and helps determine whether a battery is fully charged, partially charged, or discharged.

Key Insights Provided by OCV Testing:

State of Charge (SOC): OCV helps determine the charge level of the battery without needing to perform a discharge cycle. By measuring the voltage, manufacturers can assess how much energy is left in the battery.

Battery Health Assessment: OCV measurements can indicate if a battery is damaged or degraded. A significant drop in OCV may suggest issues like internal short circuits, cell degradation, or loss of capacity.

Performance Prediction: A battery’s OCV can also provide an estimate of its future performance under normal operating conditions. A high OCV usually correlates with better energy storage and longer cycle life.

What is IR (Internal Resistance) and Why is it Crucial?

IR (Internal Resistance) refers to the resistance within a battery that impedes the flow of current. Internal resistance is a key indicator of a battery’s efficiency and performance, directly affecting its power output, charge/discharge rates, and heat generation during use.

Key Insights Provided by IR Testing:

Efficiency and Power Loss: High internal resistance leads to increased energy loss in the form of heat, reducing overall efficiency. By testing IR, manufacturers can identify batteries that might have excessive resistance, which could result in shorter runtime and lower efficiency.

Battery Degradation: Over time, the internal resistance of a battery increases as it ages or undergoes repeated charge-discharge cycles. Elevated IR can signal that the battery has degraded or is nearing the end of its useful life, making it important for manufacturers to assess this parameter regularly.

Heat Management: Excessive internal resistance can cause overheating during charge and discharge cycles, leading to safety risks such as thermal runaway. Measuring IR helps ensure that batteries will operate within safe thermal limits.

Why Specialized Machines Are Required for OCV and IR Testing

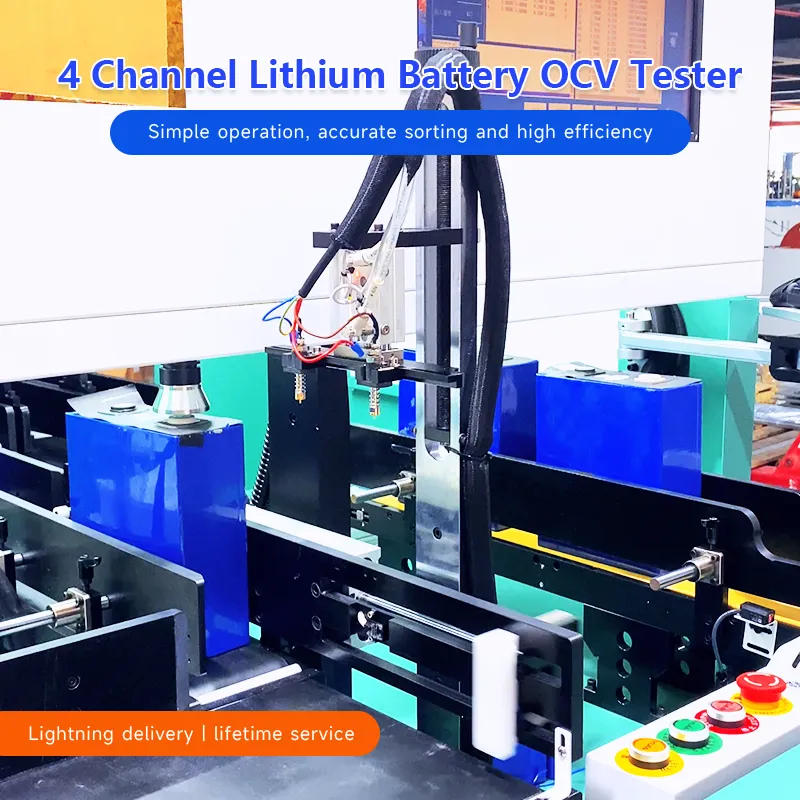

Testing OCV and IR involves precise measurements, which cannot be easily achieved through manual methods. Specialized machines designed for these tests are essential for ensuring accurate and consistent results.

Advantages of Specialized OCV and IR Testing Machines:

Precision and Accuracy: Dedicated machines are designed to provide highly accurate and consistent results, which are crucial in determining the battery’s health and performance potential. Small fluctuations in OCV or IR can indicate significant changes in battery quality, which manual testing might miss.

Automated Testing: These machines automate the testing process, reducing the need for labor-intensive manual testing and ensuring that each battery undergoes thorough testing without human error. Automated testing is especially beneficial when testing large batches of batteries in mass production environments.

Quick Turnaround: Specialized machines can test OCV and IR rapidly, allowing manufacturers to quickly assess large quantities of batteries without delays. This helps maintain production efficiency while ensuring product quality.

Comprehensive Data Collection: Testing machines not only measure OCV and IR, but also collect and store data for further analysis. This data can be used for quality control, tracking battery performance trends over time, and providing valuable insights for improving battery design.

Safety: IR testing also helps identify high-resistance batteries that may pose safety risks due to overheating. By incorporating IR testing into the production process, manufacturers can prevent potentially dangerous batteries from reaching the market.

Applications of OCV and IR Testing Machines in Battery Manufacturing

Lithium-Ion Batteries: Lithium-ion batteries, which power everything from electric vehicles to portable electronics, require regular OCV and IR testing to ensure they meet strict safety and performance standards. These tests help ensure batteries are efficient, reliable, and safe for use in high-demand applications.

Electric Vehicle Batteries: For electric vehicles, maintaining optimal battery performance is vital. OCV and IR testing are crucial for ensuring EV batteries deliver the required range, performance, and safety over the long term.

Energy Storage Systems (ESS): Batteries used in grid-scale energy storage systems need to perform reliably under demanding conditions. OCV and IR tests help ensure these batteries can maintain high efficiency and safe operation for long periods, making them ideal for large-scale applications.

Consumer Electronics: Consumer electronics such as smartphones, laptops, and tablets rely heavily on the performance and safety of their lithium-ion batteries. Regular OCV and IR testing ensures batteries in these devices operate efficiently, avoiding unexpected performance drops or safety hazards.

Conclusion

OCV and IR testing are fundamental components of battery quality control, providing valuable insights into a battery's health, performance, and longevity. With the increasing demand for high-quality, reliable, and safe batteries, these tests are essential in modern battery production. Specialized machines designed for OCV and IR testing ensure precision, speed, and reliability in the testing process, supporting manufacturers in delivering superior products to the market.

At SUNKA LEAD, we provide advanced OCV and IR testing machines designed to meet the high standards of the battery manufacturing industry. Our equipment ensures that every battery you produce is thoroughly tested for performance, safety, and efficiency. Contact us today to learn how our testing solutions can enhance your battery production process.